Best Partner for Productivity

Anchor Technologies Reshaping Tomorrow

Designing and constructing concrete structures in a professional way brings many benefits: It helps to ensure user and occupant safety over the full lifetime of the building and it drives productivity and sustainability. This is where new technologies hold the key to making construction better.

Meet two of the latest anchor-based innovations launched by Hilti.

Designing concrete-to-concrete connections with strength

Imagine standing on the banks of a wide, rushing river with a bridge connecting communities on either side. Now picture that with economic development. The populations on both sides of the bridge have grown and new industrial facilities have been built. What once used to be a bridge carrying bicycles and cars is now expected to hold trucks and buses. The bridge needs to adapt to the new demands of the community. One approach would be to demolish the old one and build a new bridge. But with the right solutions, the old bridge can be upgraded while making it more economical and sustainable for its future purposes.

This is where a professional structural engineer steps in, wearing a hard hat and ready to face the realities of jobsite conditions and complex design challenges. The engineer inspects the bridge and determines what actions should be taken to increase its ability to support high loads. This kind of strengthening rehabilitation is typically performed using a concrete overlay application.

The challenge lies in the calculations for the overlay application, as the engineer must determine the correct design approach and material specifications for the given requirements. Without the help of dedicated concrete overlay design tools, the process runs the risk of either having an overengineered non-productive design or failing to adhere to valid building codes.

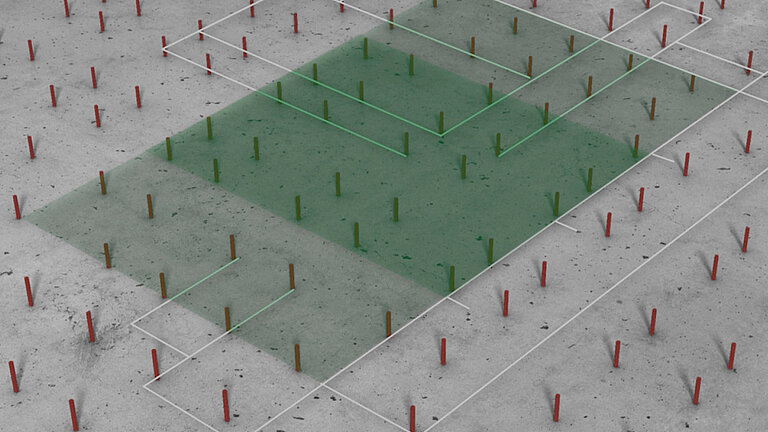

Now imagine that, in addition to strengthening, the bridge also needs to be expanded to meet the growing traffic demands of the communities. This is where concrete-to-concrete connections, done with post-installed rebar, come into play. The challenges for post-installed rebar application designs for slab or wall extensions are similar to those posed by strengthening the bridge.

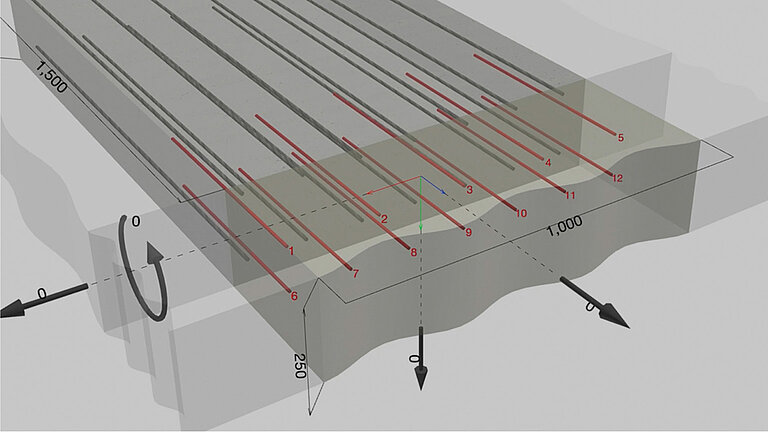

PROFIS Engineering’s two latest concrete-to-concrete design modules combine code-compliant and alternative research-based design methods to help optimize post-installed rebar and concrete overlay designs and ensure their safety. The new modules are easy to use with an intuitive user interface that enables the engineer to design productively. Additionally, both modules come with a new functionality to help the engineer calculate the CO2 emissions of the Hilti chemical anchors used to perform the applications.

PROFIS Engineering helps structural engineers be productive in performing their work and come up with more productive, safer and more sustainable designs.

Executing with excellence and accuracy

Now imagine that the contractor is preparing the upgrade of the bridge at the actual site and ready to bring the engineer’s design to life.

Following the details provided by the design engineer, the installer drills the required holes using a hollow drill bit as part of Hilti SafeSet installation. The hollow drill bit automatically cleans the drilled hole, removing the need for a separate cleaning step, making the process faster, simpler and safer. Once the holes are drilled, the installer only needs to inject the chemical anchor into the hole and insert rebar.

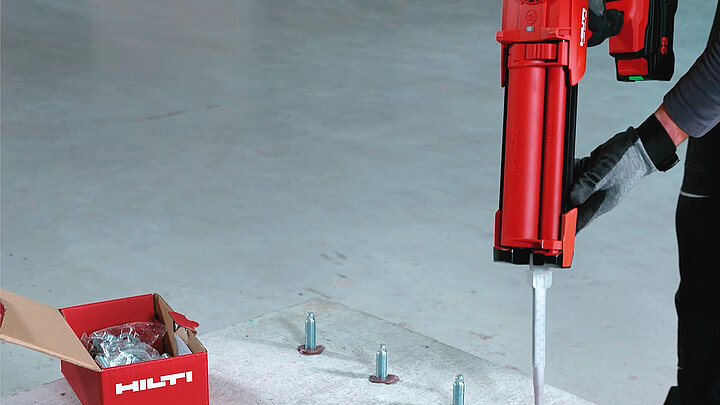

The installer can get the job done with a traditional manual dispenser, but the dose precision is entirely dependent on the competence of the installer. What if the installer had a tool that quickly doses the correct amount every time?

The all-new Nuron-powered HDE 500-22 dosing tool is this tool. The HDE 500-22’s dosing feature eliminates the guesswork and ensures the correct amount of mortar is used every time.

In the end, this seemingly simple step in the post-installed rebar application is a crucial link in the chain of construction for this bridge. Every properly installed connection can help maintain the integrity of the bridge for years to come, making the bridge stand strong and connecting the communities.

“At Hilti, we not only focus on the design aspect of the structural connection, but also consider how the structural connection impacts the actual structure. We will continue to innovate steel-to-concrete, concrete-to-concrete and timber connections, helping to ensure productivity and sustainability in structural connections,” says Marien Adema, Head of Marketing of the Anchors Business Unit.

Back to our picture of the bridge, the contractor completed the work on time, on budget and to a high standard. Designed to connect and hold whatever the future may bring. Over the years, Hilti’s commitment to research and development has transformed the way structures are built, contributing to a safer and more sustainable construction world. And Hilti will continue to drive innovation within this ever-evolving industry, leaving a lasting mark with enhanced anchor technologies, reshaping tomorrow and making construction better.

Better applications enable better construction. Discover more customer benefits which position us as the best partner for productivity.